The Hidden Art of Automotive Clay Modeling

In an era of digital design and 3D printing, one might assume that traditional sculpting techniques have no place in modern car manufacturing. However, deep within the design studios of major automakers, a time-honored craft continues to shape the vehicles of tomorrow. Automotive clay modeling, a process that dates back to the 1930s, remains an integral part of car design, blending artistry with engineering precision.

The Genesis of Automotive Clay Modeling

The use of clay in automotive design traces its roots back to Harley Earl, the legendary designer at General Motors in the 1930s. Earl, frustrated with the limitations of two-dimensional drawings, sought a more tactile and flexible medium to express his design ideas. He turned to industrial plasticine, a type of modeling clay, which allowed his team to sculpt and modify designs quickly and easily.

This innovation revolutionized the car design process. Instead of relying solely on sketches and blueprints, designers could now create three-dimensional representations of their concepts, allowing for immediate feedback and iterative improvements. The ability to walk around a full-scale model, assess proportions, and make real-time adjustments proved invaluable in refining automotive designs.

The Clay Modeling Process

The journey from concept to clay model is a meticulous one. It begins with traditional sketches and computer-aided design (CAD) renderings. Once a design is approved, a full-scale wire frame is constructed, serving as the skeleton for the clay model.

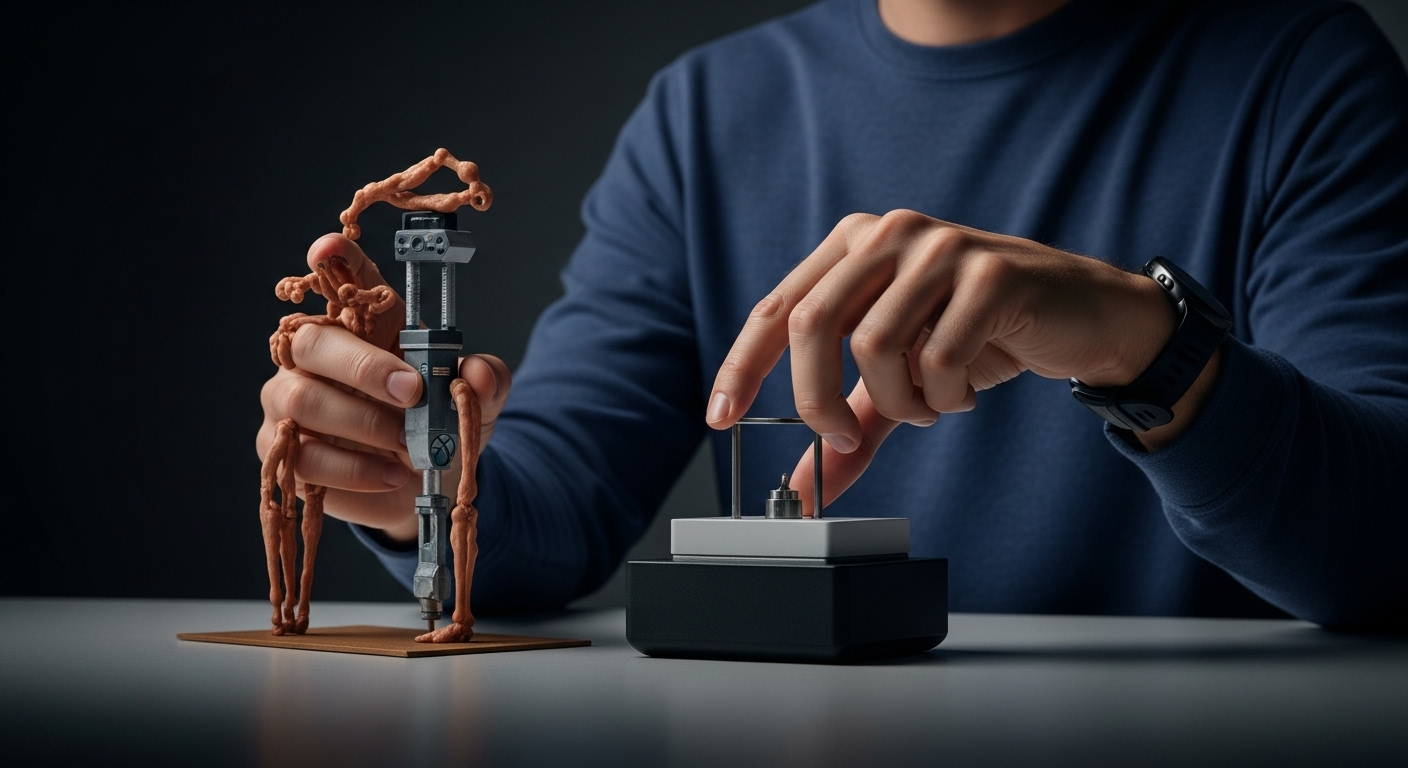

Skilled modelers then apply industrial clay to this frame, gradually building up the form of the vehicle. This clay, specially formulated for automotive use, is heated to around 66°C (150°F) to make it pliable. Modelers use a variety of tools, from large rakes to small dental instruments, to shape the clay with precision.

The Synergy of Art and Technology

While the core process remains similar to Earl’s day, modern clay modeling incorporates cutting-edge technology. Computer numerical control (CNC) milling machines can now rough out basic shapes, saving time and ensuring accuracy. However, the human touch remains crucial for refining surfaces and adding the nuanced details that bring a design to life.

3D scanning technology also plays a significant role. Clay models can be scanned and digitized, allowing for seamless integration with CAD systems. This digital data can then be used for further refinement, aerodynamic testing, or to create molds for prototype parts.

The Advantages of Physical Models

Despite advances in virtual reality and 3D visualization, clay models offer unique benefits that digital renderings cannot match. The tactile nature of clay allows designers and executives to interact with the model in ways impossible with a computer screen. They can walk around it, assess proportions from different angles, and even sit inside to evaluate ergonomics and visibility.

Clay models also reveal how light interacts with surfaces, a crucial aspect of automotive design. The play of light and shadow on a physical model can highlight issues or opportunities that might be missed in digital renderings. This real-world feedback is invaluable in creating designs that are not just beautiful in theory, but in practice as well.

The Future of Automotive Clay Modeling

As we look to the future, it’s clear that clay modeling will continue to evolve alongside digital technologies. Some automakers are experimenting with augmented reality systems that project digital elements onto clay models, creating a hybrid physical-digital design process.

However, the core value of clay modeling – its tactile, immediate, and collaborative nature – ensures its place in automotive design for years to come. As long as cars are designed to be experienced in the physical world, there will be a need for physical models in the design process.

The art of automotive clay modeling stands as a testament to the enduring value of hands-on craftsmanship in an increasingly digital world. It reminds us that even as technology advances, there’s still no substitute for the human touch in creating objects of beauty and function. As we marvel at the sleek lines of modern vehicles, we can appreciate the skilled hands that sculpted them, bridging the gap between imagination and reality, one handful of clay at a time.