Biomimetic Manufacturing: Nature-Inspired Innovation

In the quest for efficiency and sustainability, manufacturers are turning to an unlikely source of inspiration: nature itself. Biomimetic manufacturing, the practice of emulating natural processes and structures in industrial production, is revolutionizing how we approach design, production, and resource management. This innovative approach promises to unlock new levels of efficiency, durability, and sustainability in manufacturing processes across various industries.

Origins and Evolution of Biomimetic Manufacturing

The concept of biomimicry is not new, with early examples dating back to Leonardo da Vinci’s flying machine designs inspired by birds. However, the systematic application of biomimicry in manufacturing processes is a more recent development. In the 1950s, the term “bionics” was coined to describe the study of natural systems for engineering applications. This laid the groundwork for what we now call biomimetic manufacturing.

As environmental concerns grew in the late 20th century, researchers and engineers began to look more seriously at nature’s efficient, waste-free processes as potential solutions to industrial challenges. The publication of Janine Benyus’s book “Biomimicry: Innovation Inspired by Nature” in 1997 marked a turning point, bringing biomimicry into mainstream discourse and sparking interest across various industries.

Key Principles of Biomimetic Manufacturing

Biomimetic manufacturing is guided by several key principles derived from natural systems:

-

Resource Efficiency: Nature operates on a closed-loop system where waste from one process becomes food for another. Manufacturers are adopting this principle to create more circular production processes.

-

Adaptability: Natural systems are highly adaptable to changing conditions. This principle is being applied to create flexible manufacturing processes that can quickly respond to market demands.

-

Resilience: Nature builds redundancy and diversity into its systems, ensuring resilience. Manufacturers are incorporating these principles to create more robust supply chains and production processes.

-

Energy Efficiency: Natural processes are incredibly energy-efficient. By mimicking these processes, manufacturers can significantly reduce their energy consumption.

-

Multi-functionality: In nature, single structures often serve multiple purposes. This principle is being applied to create multi-functional materials and products, reducing complexity and resource use.

Applications in Modern Manufacturing

Biomimetic manufacturing is finding applications across a wide range of industries:

-

Aerospace: The aviation industry is using shark skin-inspired textures to reduce drag on aircraft, leading to significant fuel savings.

-

Construction: Buildings inspired by termite mounds are being designed with passive cooling systems, dramatically reducing energy consumption.

-

Textiles: Fabrics with self-cleaning properties inspired by lotus leaves are being developed, reducing the need for water and chemicals in cleaning processes.

-

Automotive: Car manufacturers are using honeycomb structures to create lighter, stronger vehicle components, improving fuel efficiency and safety.

-

Robotics: Soft robotics inspired by octopus tentacles are being developed for applications in manufacturing and medicine, offering greater flexibility and adaptability.

Challenges and Future Prospects

Despite its promise, biomimetic manufacturing faces several challenges. Translating biological principles into industrial processes can be complex and time-consuming. There’s also a need for interdisciplinary collaboration between biologists, engineers, and designers to effectively implement biomimetic solutions.

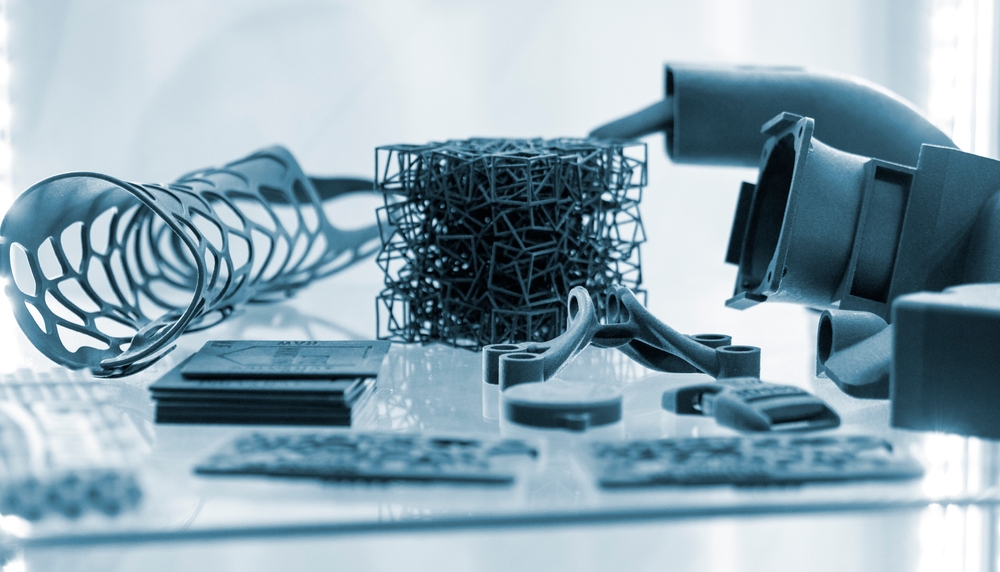

However, the potential benefits are substantial. As we face increasing environmental pressures and resource constraints, biomimetic manufacturing offers a path to more sustainable and efficient production processes. Advances in materials science, nanotechnology, and 3D printing are opening up new possibilities for mimicking nature’s intricate structures and processes at various scales.

Key Insights for Implementing Biomimetic Manufacturing

• Start with function: Focus on the function you want to achieve rather than trying to copy a specific organism.

• Embrace interdisciplinary collaboration: Bring together biologists, engineers, and designers to foster innovative solutions.

• Think in systems: Consider how your biomimetic solution fits into the broader ecosystem of your industry.

• Invest in research and development: Biomimetic solutions often require significant upfront investment but can lead to long-term gains.

• Look beyond direct mimicry: Sometimes, the principles behind natural processes are more valuable than exact replication.

As we continue to face complex industrial challenges, biomimetic manufacturing offers a promising approach to innovation. By learning from and emulating nature’s time-tested strategies, manufacturers can create more efficient, sustainable, and adaptive processes. The future of manufacturing may well be written in the language of nature, offering solutions that are not only cutting-edge but also harmonious with our environment.